Case Study Cracked Annealed EVA Film Laminated Glass with Fabric Inserted

Case Study: Cracked Annealed EVA Film Laminated Glass with Fabric Inserted

By Peter Lin

Glass Questions

One glass friend ask questions of EVA film laminated glass on the LINKEDIN group:

http://www.linkedin.com/groups/EVA-GLASS-LAMINATING-4147748

Cracked annealed laminated glass with fabric

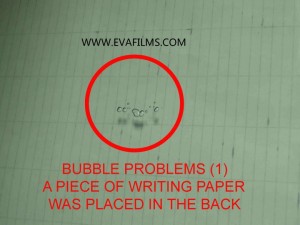

I’ve got some samples from various eva suppliers(Note this is not CNCGLASS EVA). We tried it on the fabric and the only problem with them after they were processed was the bubbles around the edges. After 3 weeks, we found out that most of them have cracks, which does not happened to eva laminated glass without fabric. The crack was edge to edge and in the middle of the pane.

Glass Answers

Here is the reasons and solutions of the glass question answered by Peter Lin

First, let’s analyze the question.

Situation 1-When you just make EVA Film laminated glass(without fabric) you don’t have the bubbles.

Situation 2-When you make fabric EVA laminated glass (fabric inserted), you have bubbles around edges.

Here is the reasons and solutions:

1-You should use thicker EVA film (for example, change from 0.38MM to 0.76MM) when you are laminating with fabric. You need more EVA film to fill the surface gap of the glass and fabric.

2-You should use the EVA film that is better in melt flow index. Which means, the melting EVA film is easier to flow to fill all the gaps and surface of the glass and the fabric.

3-If the glass is cracked in edges and in the middle, you should use the EVA film (for example CNC GLASS EVA FILM) that is eliminated the internal strength of the EVA film when the EVA film is produced on the EVA extruded producing line. So the EVA film will be less at expanding with heat and contracting with cold.

4-Check if the fabric you use is sensitive at expanding with heat and contracting with cold, if so, please try to find a one which is more stable at expanding with heat and contracting with cold.

Hope we answer your question.

If you have any other questions, please don’t hesitate to contact us.

Our email is cnc@cncglass.com.

All rights reserved by CNC GLASS INTERLAYER TECH:

Product 1]CNC EVA FILM INERLAYER FOR ARCHITECTURAL LAMINATED GLASS

eva@evafilms.com

Product 2]CNC PDLC SMART GLASS FILM FOR PRIVACY SWITCHABLE GLASS

smartfilm@smartestglass.com

Product 3]CNC PVB FILM INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS

www.cncglass.com